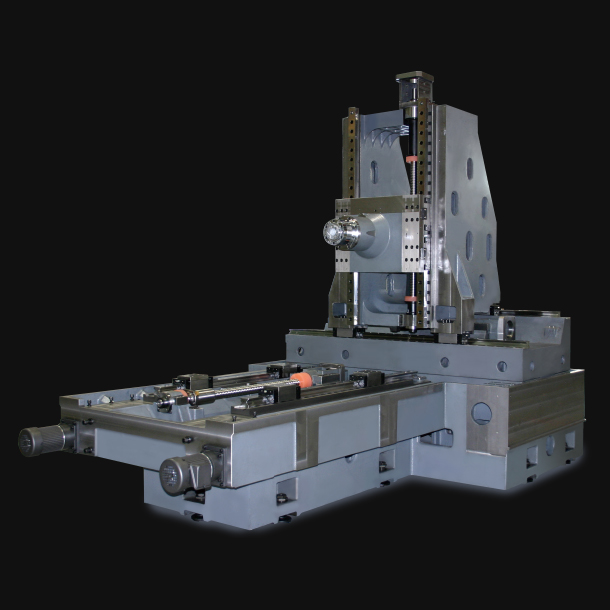

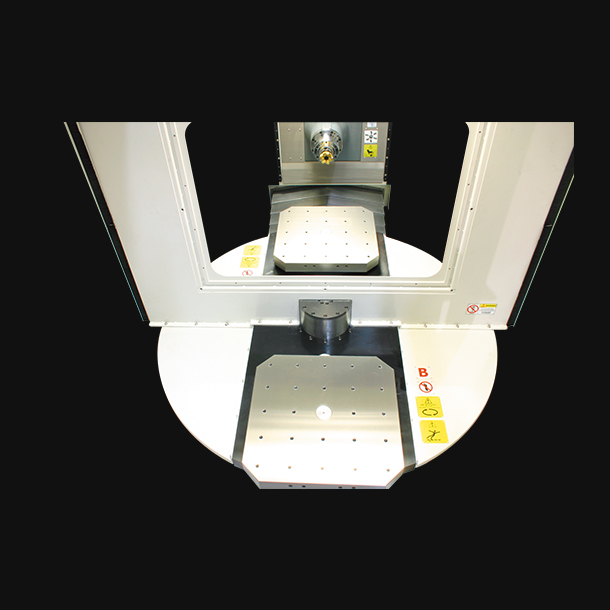

Horizontal Machining Center

YHM-500

- Features

- Standard Spindle Speed: 12000 rpm

- X/Y/Z travel: 700/660/630 mm

- X/Y/Z Rapid: 60/48/60 m/min

- Max. load capacity: 600 kg

- Standard Spindle Taper: ISO No. 40

Specifications

Accessories

| ITEM | SPECIFICATION | YHM-500 | |

| Table | Size | 500×500mm(19.7"x19.7") | |

| Screw Holes | M12×P1.75 | ||

| Max. Load Capacity | 600kg(1320lbs) | ||

| Min. Index Angle | 0.001° [*0.0001°] | ||

| Numble of Pallets | 2 | ||

| Pallet Surface to Floor | 1000mm(39.4") | ||

| Travel | X Aixs | 700mm(27.6") | |

| Y Aixs | 660mm(26") | ||

| Z Aixs | 630mm(24.8") | ||

| Spindle Nose to Pallet Center | 105 ~ 735mm(4.1"~28.9") | ||

| Spindle Center to Pallet Surface | 105 ~ 765mm(4.1"~30") | ||

| Max. working piece | Φ630*H765 | ||

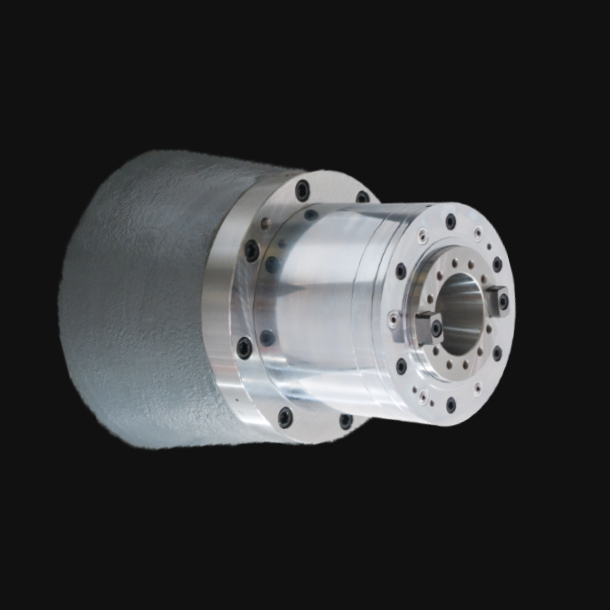

| Spindle | Taper | ISO No.40 | |

| Diameter | Φ70m(Φ2.8") | ||

| Max. Speed | 12000rpm | ||

| Transmission | Direct-Drive | ||

| Motor | 15kW (20hp) | ||

| Max. Torque | 11.6kg-m(114N-m) | ||

| ATC | Capacity | 60 | |

| Selection | Bi-Directional | ||

| Max. Tool Diameter x Length | Φ80mm x300 mm (Φ3.1"x11.8") | ||

|

Max. Tool Diameter |

Φ160mm(Φ6.3") | ||

| Max. Tool Weight | 8㎏(17.6lbs) | ||

| Tool Holder Type | BT40 | ||

| Axes | Servo Motor X,Y,Z axes | X: 4kW, Y:7kW, Z: 4kW (5.4/9.4/5.4hp) |

|

| Servo Motor B axis | 1.6kW(2.1hp) | ||

| Cutting Feed Rate | 24m/min | ||

| Rapid and Jog Feed Rate | X,Z: 60m/min ; Y: 48m/min | ||

| CNC Controller | FANUC 0iMD [*31iMB] | ||

| Motor | Chip Conveyor Motor | 188 W (1/4hp) | |

| Coolant Pump Motor | 1510 W(2.01hp) | ||

| Flush Pump Motor | 1510 W(2.01hp) | ||

| Hydraulic Oil Tank Motor | 1510 W(2.01hp) | ||

| Coolant Tank | Tank Capacity | 750L | |

| Pump Capacity | 130L/min | ||

| Dimension | Floor Space(LxWxH)(Approx.) | 3880mm×4250mm×2830mm (153"x167"x111") |

|

| Net Weight(Approx.) | 13000kg(28600lbs) | ||

| Gross Weight(Approx.) | 16000kg(35200lbs) | ||

| 220V/60HZ | |||

Accessories

| Standard accessories | |||

| 1. | FANUC 0i-MD Controller | 13. | Manual Pulse Generator (Hand wheel) |

| 2. | Spindle Speed: 12000rpm | 14. | Rigid Tapping |

| 3. | Spindle Oil Cooler | 15. | Auto Power Off |

| 4. | Spindle Air Blow System | 16. | Fully Enclosure |

| 5. | Spindle Air Curtain System | 17. | Chain Type Chip Conveyor |

| 6. | Auto Pallet Change | 18. | Chip Cart |

| 7. | 2 Pallets | 19. | Screw Type Chip Conveyor(2 sides) |

| 8. | 0.001°Index pallet | 20. | Working Light |

| 9. | Coolant System | 21. | Warning Light |

| 10. | Flush System | 22. | Tool Kit |

| 11. | Hydraulic System | 23. | Leveling Bolt and Pad |

| 12. | Auto Lubrication System | 24. | Aicc function/40 blocks(Fanuc) |

| Optional accessories | |||

| 1. | FANUC 31i-MB Controller | 10. | Oil Mist Collection System |

| 2. | Spindle Speed: 15000rpm | 11. | Oil Skimmer |

| 3. | CTS (closing pressure:40/70 bar) | 12. | Scrape Type Chip Conveyor |

| 4. | T-slot Pallet | 13. | Transformer |

| 5. | DD Motor Driven System(B-axis) | 14. | Air/hydraulic oil source interface |

| 6. | 3-axes Optical Scale | 15. | Base clamping place device |

| 7. | Auto.Tool Length Measurement | 16. | Data Server(Fanuc) |

| 8. | Auto. Part Measurement | 17. | Aicc Ⅱ Function / 200 Blocks(Fanuc) |

| 9. | Oil Mist Cutting System | ||